What is belt conveyor: indispensable part of transportation

Belt conveyor is a fast and efficient mechanical device for automatically transporting loads and materials within an area. They are one of the many types of conveyor systems available today and they are common throughout all industrial applications.

Generally conveyors are used to transport bulk materials in material handling industry. The range of tasks is depending on the weight required, the speed required and the throughput of products on the conveyor system. The belt conveyor minimizes human error and lowers the risk of the workplace and reduces label cost.

Generally, the belt is composed of one or more layers of materials. Most belts in general material handling consist of two layers. Carcass is the name of the under layer that provides linear strength and shape, while cover is the name of the over layer. Polyester, nylon and cotton are used most often to create the carcass, while a variety of rubber or plastic compounds specified by use of the belt are used to create the cover.

Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them. One or more of the pulleys will be powered moving the belt and the material on the belt forward and along the system.

● Time saving

Belt conveyor can make it convenient to move the goods up and down floor, whch achieves the efficient transport of large volumes of items with short time consumption. Also it may lead to physical strain if the goods are moved manually by human.

● Labor saving

Belt conveyor can help transport the items which are too heavy or too bulky for humans to carry by hand.

● Space saving

The use of belt conveyor is also space efficient because it needs less space and personnel to move the goods.

● Lower price

Generally the belt conveyor is cheaper than other conveyor system. Conveyor belts are also useful in instances where the use of a roller conveyor system for example would be unsuitable due to items being too light, having irregular bottomed surfaces, or also being too small. Consequently, these items may not move, could slip, or even get stuck in the rollers.

Due to conveyor systems being adaptive, they are able to be used in most industries due to the variation of weight, length, and items they can carry. Conveyor belt is the fundamental element for the transport of items in a wide range of industries. Considering the huge range of utilities and considering the diversity of the transported products, the design options and manufacturing materials of the conveyor belts are very diverse.

● Logistic and distribution center

The conveyor belts are a basic element of any warehouse in a distribution center or logistics company. Most of the items are carried out thanks to conveyor belts.

● Restaurant

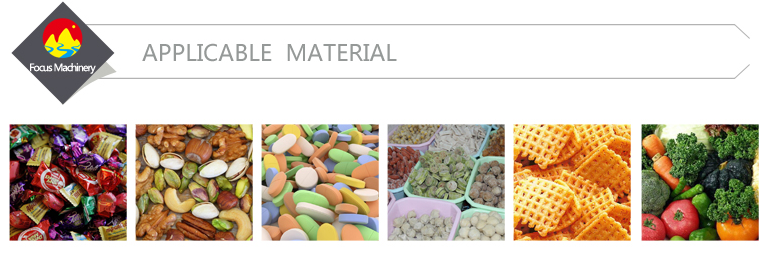

Food is conveyed in the food grade belt conveyor for customers to choose, and it can avoid the food or plates falling between sections.

● Quarries and heavy industries

This conveyor is characterized by having to support heavy loads and move materials with great capacity of erosion or corrosive, Therefore, they are conveyor belts of very specific characteristics of great resistance to abrasion and high temperatures.

● Baggage transfer

All the baggage transfer that takes place in an airport or metro stations is done through belts or roller conveyors. Most of the baggage movements are carried out thanks to conveyor belts. As well as baggage, a large number of people are moved through conveyor belts in airport facilities, train stations or subway exchangers.

● Production system

Any manufacturing system at the industrial level includes conveyor belts that move the products between different points of processing, storage or distribution.

Focus Machinery Co., Ltd is one of the belt conveyor manufacturers in China. We are committed to designing and manufacturing premium conveyors. Our products mainly includes bucket elevator, inclined belt conveyor, flat conveyor, stainless steel belt convey or screw conveyor, gravity conveyor, spiral conveyor, etc. Our Machines are widely applied in various industries, such as plastic, electronic, chemical, food, textile, printing, medicine, which greatly improve the working efficiency and lower the labor costs.

►►Other Conveyors Articles◄◄

How does a belt conveyor work?

Purchasing Guide for Bucket Conveyors

Generally conveyors are used to transport bulk materials in material handling industry. The range of tasks is depending on the weight required, the speed required and the throughput of products on the conveyor system. The belt conveyor minimizes human error and lowers the risk of the workplace and reduces label cost.

Generally, the belt is composed of one or more layers of materials. Most belts in general material handling consist of two layers. Carcass is the name of the under layer that provides linear strength and shape, while cover is the name of the over layer. Polyester, nylon and cotton are used most often to create the carcass, while a variety of rubber or plastic compounds specified by use of the belt are used to create the cover.

Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them. One or more of the pulleys will be powered moving the belt and the material on the belt forward and along the system.

Why Are Belt Conveyors Used

● Time saving

Belt conveyor can make it convenient to move the goods up and down floor, whch achieves the efficient transport of large volumes of items with short time consumption. Also it may lead to physical strain if the goods are moved manually by human.

● Labor saving

Belt conveyor can help transport the items which are too heavy or too bulky for humans to carry by hand.

● Space saving

The use of belt conveyor is also space efficient because it needs less space and personnel to move the goods.

● Lower price

Generally the belt conveyor is cheaper than other conveyor system. Conveyor belts are also useful in instances where the use of a roller conveyor system for example would be unsuitable due to items being too light, having irregular bottomed surfaces, or also being too small. Consequently, these items may not move, could slip, or even get stuck in the rollers.

What Are The Types Of The Belt Conveyors?

● Flat belt conveyors

Flat belt conveyor belts are currently one of the most commonly used conveyors in various industries. It is composed of a flat belt and a series of powered pulley. A set of power pulleys move the flat belt to realize the transportation of objects. Flat belt conveyors can transport scattered, fragile or irregularly shaped items without damaging them.

90 degree conveyor belt specification:

| Model | 90 degree turning belt conveyor 90 degree belt conveyors |

| Machine Frame | 304 stainless steel or carbon steel |

| Belt Material | PP belt, PVC belt, PU belt, Stainless steel belt |

| Machine Height | To be customized |

| Voltage | AC220v or three phase 380v, 50hz/60hz |

| Power Supply | 1.1kw |

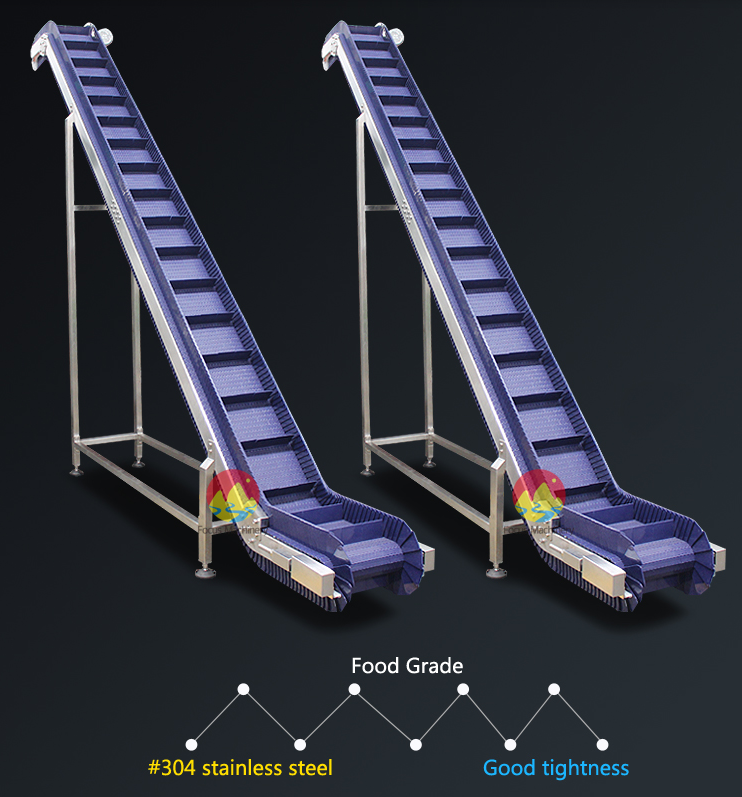

●Inclined belt conveyor

When products must be transported upwards, then you should consider inclined belt conveyors. The conveyor belt can be equipped with a carrier or high friction belt material to ensure that the product will not roll off or slip. Inclined bowl conveyor is also a good choice to transport items.●Spiral belt conveyor

Vertical spiral belt conveyor is a safe and reliable transport and have a function of continuous down moving. Spiral Screw Conveyor, or spiral conveyor is a kind of conveying equipment widely used in chemical, building materials, grain and other departments. It is mainly used to transport powdery, granular and small block materials.● Roller Bed Conveyor Belts

The surface of this roller bed conveyor belt is composed of rollers, and then the items are loaded onto the conveyor belt. Roller-bed conveyor belts can reduce friction and make products easier to move along the conveyor belt, so they are ideal for long-distance transportation of items.● Curved Belt Conveyors

This type of curve belt conveyor has a curved frame design, which is very suitable for transporting items around corners and makes full use of the available space. It is usually used in bag handling systems.● Modular belt conveyors

The modular belt conveyor is ideal for applications involving corner movement. It is made of a single loop made of countless interlocking pieces. These plastic parts can be disassembled and replaced separately, so this conveyor belt is very easy to clean and maintain.

Where are conveyor belts used?

Due to conveyor systems being adaptive, they are able to be used in most industries due to the variation of weight, length, and items they can carry. Conveyor belt is the fundamental element for the transport of items in a wide range of industries. Considering the huge range of utilities and considering the diversity of the transported products, the design options and manufacturing materials of the conveyor belts are very diverse.

● Logistic and distribution center

The conveyor belts are a basic element of any warehouse in a distribution center or logistics company. Most of the items are carried out thanks to conveyor belts.

● Restaurant

Food is conveyed in the food grade belt conveyor for customers to choose, and it can avoid the food or plates falling between sections.

● Quarries and heavy industries

This conveyor is characterized by having to support heavy loads and move materials with great capacity of erosion or corrosive, Therefore, they are conveyor belts of very specific characteristics of great resistance to abrasion and high temperatures.

● Baggage transfer

All the baggage transfer that takes place in an airport or metro stations is done through belts or roller conveyors. Most of the baggage movements are carried out thanks to conveyor belts. As well as baggage, a large number of people are moved through conveyor belts in airport facilities, train stations or subway exchangers.

● Production system

Any manufacturing system at the industrial level includes conveyor belts that move the products between different points of processing, storage or distribution.

►►Other Conveyors Articles◄◄

How does a belt conveyor work?

Purchasing Guide for Bucket Conveyors