The Application of Various Conveyor Belt Types in Conveyor Systems

Introduction: Conveyor belts are essential components of material handling systems, facilitating the efficient movement of goods in various industries. Different types of conveyor belts are available, each designed to suit specific applications based on factors such as material type, load capacity, speed, and environmental conditions. This paper explores the application of various belt types in conveyor systems, highlighting their unique characteristics and suitability for different industries and environments.

-

Flat Belts: Flat belts are among the most commonly used conveyor belts, featuring a simple design with a flat surface for carrying loads. They are ideal for transporting lightweight to medium-weight materials over short to medium distances. Flat belts find applications in industries such as manufacturing, food processing, and packaging, where smooth and consistent material handling is essential. Additionally, flat belts are suitable for incline or decline conveyors due to their flexibility and ease of tracking.

-

Modular Plastic Belts: Modular plastic belts consist of interlocking plastic modules linked together with hinge rods, providing a durable and versatile conveying solution. These belts offer excellent flexibility, allowing them to conform to various conveyor configurations, including curves and inclines. Modular plastic belts are resistant to corrosion, abrasion, and moisture, making them suitable for industries such as automotive manufacturing, beverage processing, and pharmaceuticals. Their modular design facilitates easy cleaning and maintenance, ensuring hygienic material handling in food and beverage applications.

-

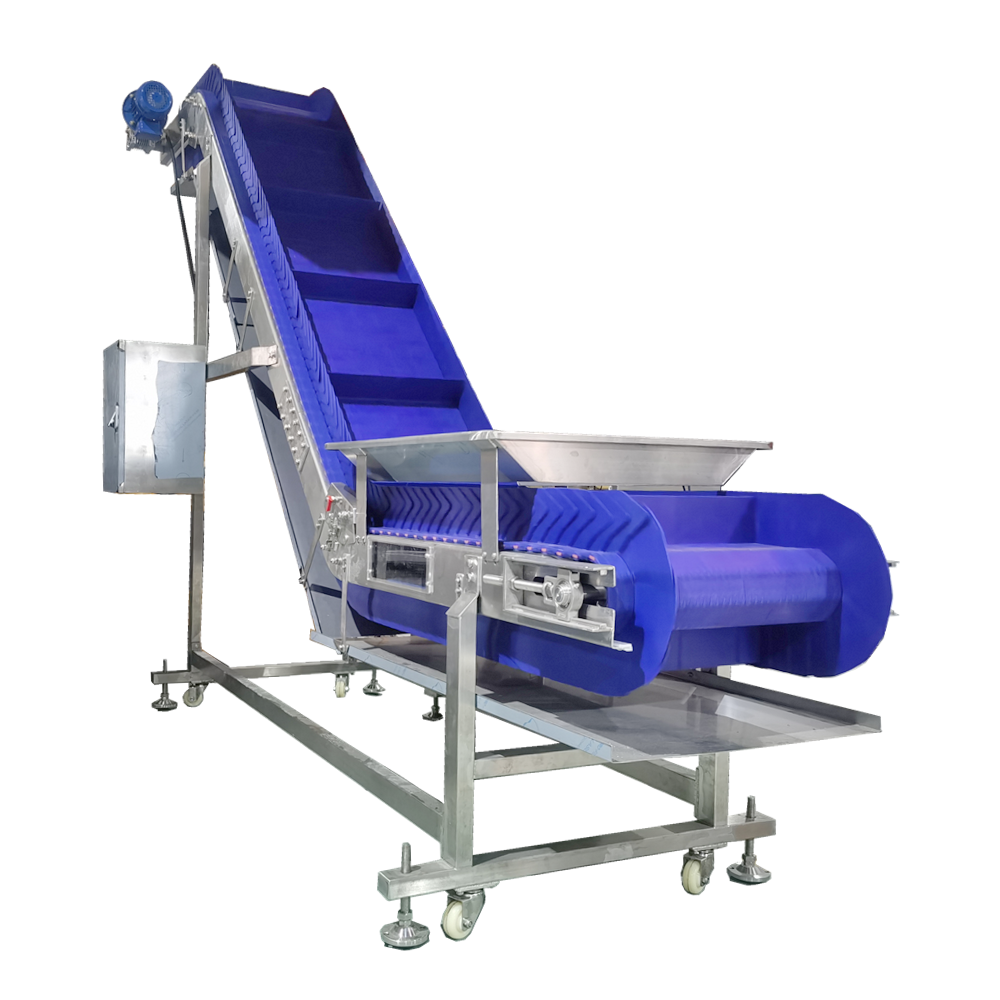

Cleated Belts: Cleated belts feature raised sections or cleats along their surface, providing enhanced grip and stability for transporting inclined or steeply inclined materials. These belts prevent material slippage and allow for steeper conveyor angles, making them ideal for handling bulk materials, such as grains, aggregates, and bulk solids. Cleated belts find applications in industries such as agriculture, mining, and construction, where reliable and efficient transport of bulk materials is essential. Additionally, cleated belts are available in various cleat profiles and heights to accommodate specific material handling requirements.

-

Timing Belts: Timing belts, also known as synchronous belts, feature toothed profiles that mesh with corresponding pulleys to ensure precise and synchronous movement. These belts offer accurate positioning and high-speed operation, making them suitable for applications requiring precise product placement and synchronization, such as assembly lines, packaging machinery, and automotive manufacturing. Timing belts are resistant to wear and stretch, providing long-lasting performance and minimal maintenance requirements.

-

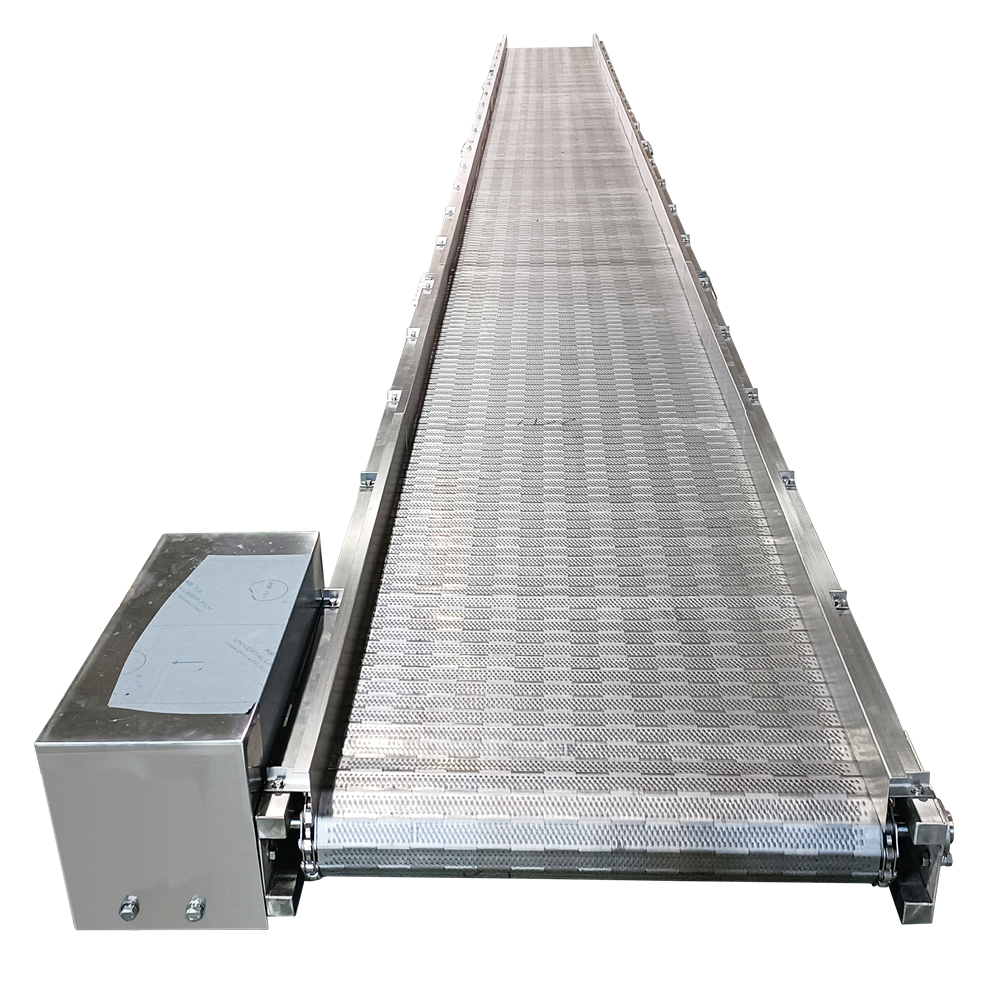

Wire Mesh Belts: Wire mesh belts consist of interwoven metal wires or mesh panels, providing an open and breathable conveying surface. These belts offer excellent airflow and drainage properties, making them ideal for applications involving heating, cooling, or washing processes. Wire mesh belts are commonly used in industries such as food processing, baking, and automotive painting, where thermal processing, sanitation, or liquid drainage are critical requirements. Additionally, wire mesh belts are resistant to high temperatures, corrosion, and chemical exposure, ensuring durability in harsh operating environments.

Conclusion: In conclusion, the selection of the appropriate conveyor belt type is crucial for optimizing material handling processes in various industries. Understanding the characteristics and applications of different belt types allows for the efficient design and operation of conveyor systems tailored to specific requirements. Whether it's flat belts for smooth material transport, modular plastic belts for versatile configurations, cleated belts for inclined material handling, timing belts for precise synchronization, or wire mesh belts for specialized applications, each belt type offers unique advantages that contribute to efficient and reliable material handling operations.