A Conveyor Do Not Have To Be Manually Cleaned:Automatic Clean Belt Conveyors

Introduction

Conveyors are essential components in various industries, particularly in food processing, pharmaceuticals, and manufacturing. Traditional conveyor systems require extensive manual cleaning, which is time-consuming, labor-intensive, and costly. In response to these challenges, we introduce our Automatic Clean Belt Conveyors, designed to streamline operations and maintain hygiene standards effortlessly.

Problem Statement

Manual cleaning of conveyor belts is a significant bottleneck in operational efficiency. Daily cleaning processes not only slow down production but also pose risks of contamination if not done thoroughly. This paper discusses how our innovative automatic clean belt conveyors address these issues with advanced self-cleaning mechanisms and superior design features.

Product Overview

Our Automatic Clean Belt Conveyors are equipped with cutting-edge technology to ensure high efficiency and hygiene:

- Water Sprinkler System: Integrated water sprinklers automatically wash the conveyor belt, removing debris and residues.

- Air Blower: Following the wash, powerful air blowers dry the belt, preventing mold and bacterial growth.

- Food Grade PU Belt: The conveyor belt is made from durable, food-grade polyurethane, ensuring safety and compliance with food industry standards.

- Stainless Steel Frame: The machine frame is constructed from stainless steel, offering robustness and resistance to corrosion.

- IP65 Waterproof Motor: Our conveyor features an IP65-rated waterproof motor, safeguarding against water ingress during cleaning.

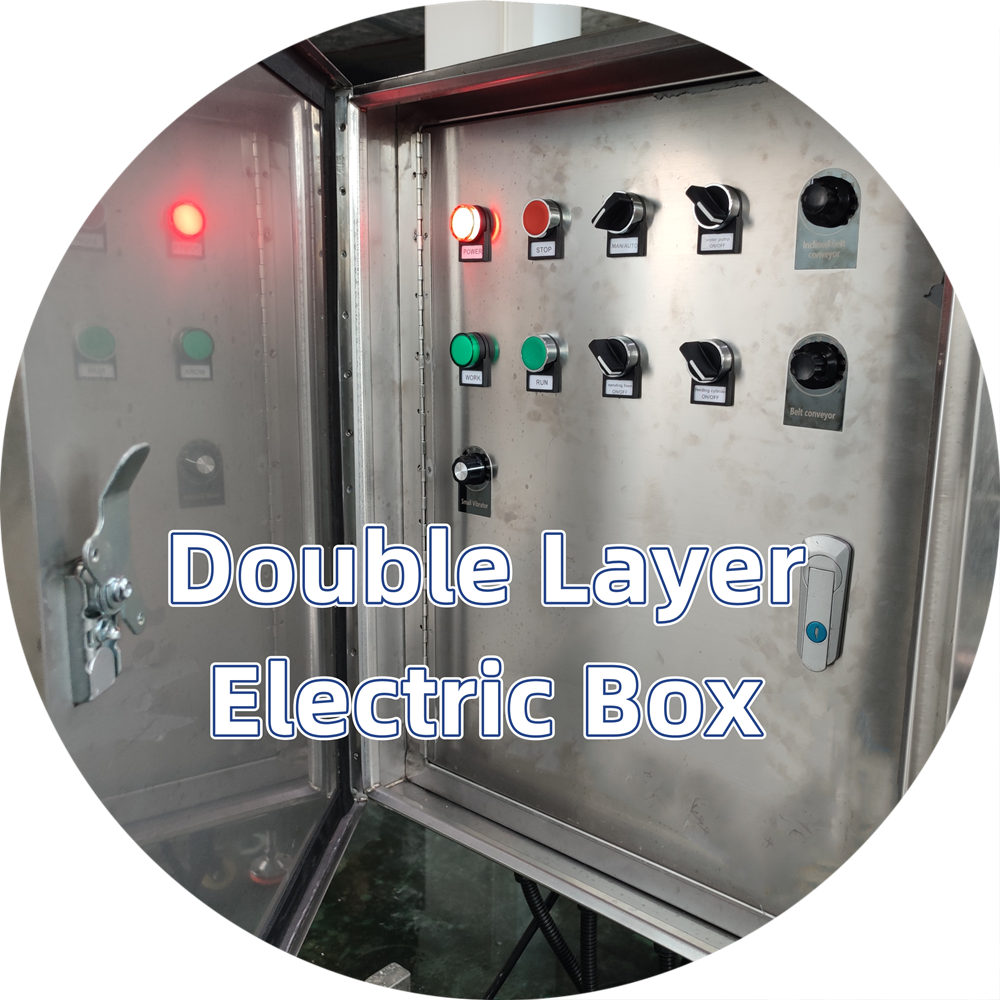

- Double Layer Electric Box: The electric box has a double layer design for enhanced protection against moisture and dust.

- Easy Installation and Removal: The conveyor is designed for easy installation and removal, facilitating maintenance and reducing downtime.

Benefits of Automatic Clean Belt Conveyors

- Time Efficiency: Automated cleaning reduces the need for manual intervention, allowing continuous operation and minimal downtime.

- Enhanced Hygiene: Consistent and thorough cleaning ensures higher hygiene standards, critical in food processing and pharmaceutical industries.

- Cost Savings: Reduced labor costs and minimized production halts translate to significant cost savings.

- Durability and Compliance: High-quality materials and compliance with industry standards ensure long-lasting performance and safety.

- Ease of Maintenance: Simplified installation and removal processes make maintenance straightforward and less frequent.

Technical Specifications

- Water Sprinkler System: Adjustable nozzles, customizable spray patterns.

- Air Blower: High-velocity fans, adjustable airflow.

- PU Belt: FDA-approved, wear-resistant, and easy to clean.

- Stainless Steel Frame: Grade 304 or 316 stainless steel options.

- Motor: IP65-rated, energy-efficient with variable speed control.

- Electric Box: Sealed double layer, IP66-rated components.

- Structure: Modular design for quick assembly and disassembly.

Use Cases and Applications

- Food Processing Plants: Ensuring contamination-free production lines.

- Pharmaceutical Manufacturing: Maintaining sterile environments.

- Packaging Industries: Speeding up processes without compromising hygiene.

- Automotive and Electronics: Keeping production lines clean and efficient.

Conclusion

Our Automatic Clean Belt Conveyors represent a significant advancement in conveyor technology. By integrating automated cleaning systems with durable and compliant materials, we offer a solution that enhances productivity, hygiene, and cost-efficiency. Adopting this technology can transform operations across various industries, making daily manual cleaning a thing of the past.

Call to Action

We invite you to explore the future of conveyor systems with our Automatic Clean Belt Conveyors. Contact us on whatsApp 86 18929972670 for a demonstration and see firsthand how this innovative solution can benefit your operations.