U-Type Screw Conveyor: Conveying Efficiency, Easy Cleaning, and Food Safety

Introduction

In industries that deal with the transportation of bulk materials, screw conveyors play a vital role. Among the various types of screw conveyors available, the U type screw conveyor stands out as a versatile and efficient solution. This article aims to delve into the importance and benefits of U type screw conveyors, particularly in conveying different kinds of powder and small granules. Furthermore, we will explore two additional features that enhance their usability: the acrylic glass door for easy cleaning and the food-grade full 304 stainless steel construction, ensuring compliance with industry standards.

The primary function of a U type screw conveyor is to transport various types of powder and small granules within a processing system. This type of conveyor is widely used in industries such as agriculture, food processing, pharmaceuticals, and chemicals, among others. It facilitates the smooth and efficient movement of materials along an inclined or horizontal path.

a. Agricultural Industry: U type screw conveyors are indispensable in the agricultural sector for conveying materials like grain, seeds, fertilizers, and animal feed. They enable seamless transfer between different stages of the production process, such as loading, mixing, and packaging.

b. Food Processing Industry: In the food industry, U type screw conveyors are used for handling ingredients like flour, sugar, spices, and additives. The conveyor's gentle handling and enclosed design prevent contamination and ensure the quality and safety of the conveyed materials.

c. Pharmaceutical and Chemical Industries: U type screw conveyors are also extensively employed in the pharmaceutical and chemical sectors for transporting powders, additives, and other small granules. These conveyors provide a hygienic and efficient solution while maintaining product integrity.

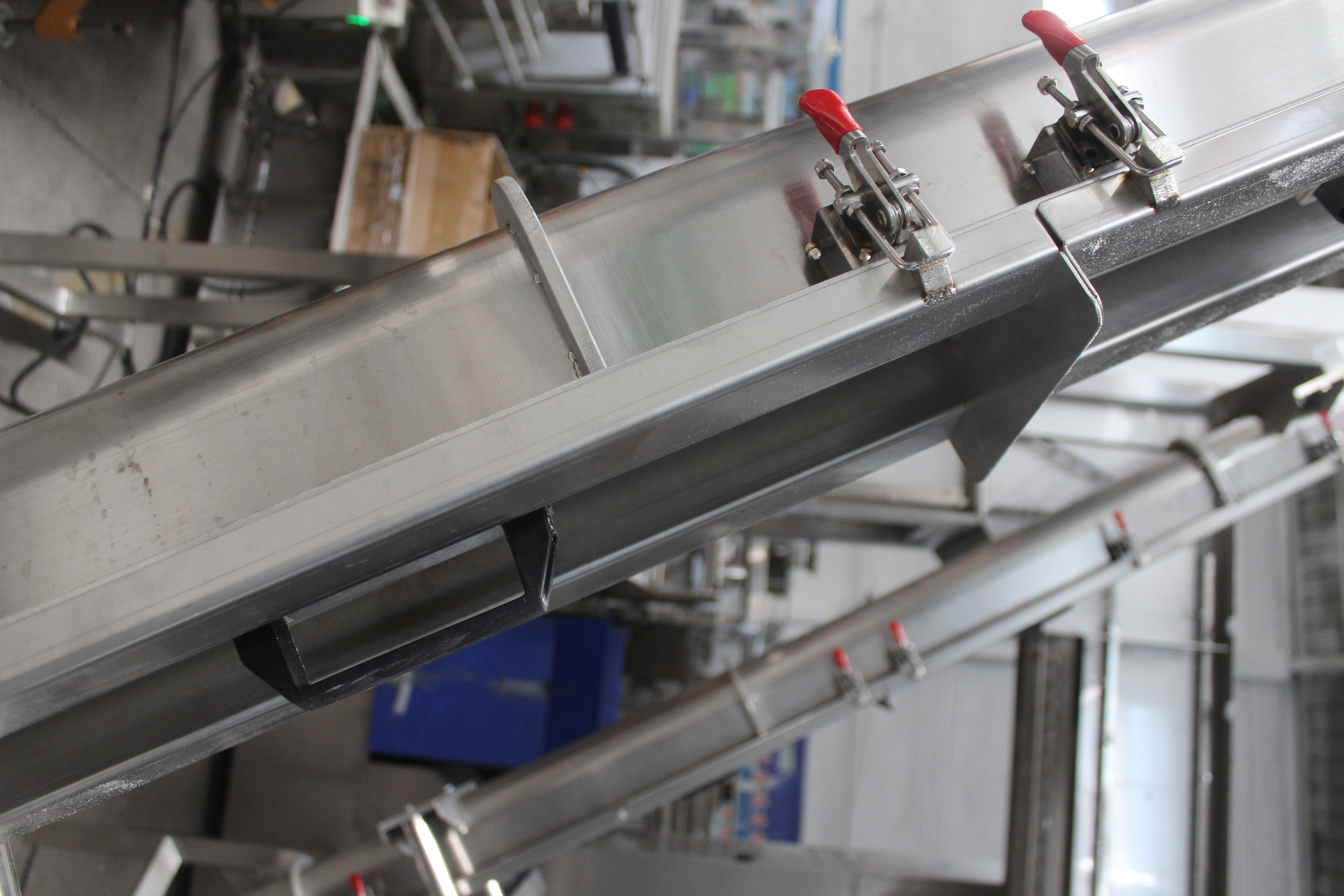

One notable feature of U type screw conveyors is the presence of an acrylic glass door. This door provides easy access to the interior of the conveyor, facilitating swift cleaning and maintenance. The transparent nature of acrylic glass allows operators to monitor the material flow, ensuring smooth operation and preventing potential blockages.

a. Enhanced Efficiency: The ability to clean the conveyor quickly reduces downtime between material changes or batch production runs. This feature is particularly crucial in industries where cross-contamination must be minimized or eliminated.

b. Hygiene and Safety: The acrylic glass door ensures that the conveyor's interior is kept clean and free from any residue or foreign particles that may cause contamination. By adhering to strict hygiene standards, U type screw conveyors contribute to the production of safe and high-quality products.

Another important aspect of U type screw conveyors is their construction using food-grade full 304 stainless steel. This material choice ensures compliance with food safety regulations and industry standards. Let's explore the benefits of this feature:

a. Corrosion Resistance: Stainless steel's inherent corrosion resistance properties make U type screw conveyors suitable for applications involving acidic or alkaline materials. This resistance ensures the longevity and durability of the conveyor, reducing maintenance costs and enhancing operational efficiency.

b. Cleanliness and Sanitation: The smooth, non-porous surface of stainless steel prevents the accumulation of particles and facilitates easy cleaning. Additionally, stainless steel is resistant to bacterial growth, making U type screw conveyors ideal for industries with stringent hygiene requirements.

c. Material Integrity: The use of food-grade stainless steel ensures that the conveyed materials remain uncontaminated and unaltered during transportation. It eliminates the risk of product degradation, maintaining the quality and consistency of the end products.

Conclusion

U type screw conveyors provide a reliable and efficient solution for conveying various powders and small granules across different industries. Their ability to handle diverse materials makes them an essential component in agricultural, food processing, pharmaceutical, and chemical sectors. The inclusion of an acrylic glass door simplifies cleaning and maintenance procedures, contributing to operational efficiency and product integrity. Moreover, the construction of U type screw conveyors using food-grade full 304 stainless steel ensures compliance with hygiene standards while offering corrosion resistance and material integrity.

As industries continue to evolve, U type screw conveyors will remain a critical part of material handling systems, contributing to increased productivity and maintaining product quality.

Sources:

- "Screw Conveyor Design: The Essential Guide to Those Beautiful Archimedean Screws," Powder Process-Solutions.

- "Choosing the Right Conveyor: A Complete Guide to Selecting the Best Conveyor for Your Process," Flexicon Corporation.

- "Screw Conveyor Corporation Catalog," Screw Conveyor Corporation.

- "Food Processing Industry: Conveying Systems and Manufacturing Solutions," Spiroflow Systems Inc.

- "Stainless Steel for Food Processing: Grades, Applications, and Benefits," Clinton Aluminum.

- "304 Stainless Steel Properties," Engineers Edge.