Revolutionizing Material Handling: The Multi-Outlet Bucket Conveyor System

Introduction

In the realm of industrial innovation, the multi-outlet bucket conveyor system has emerged as a game-changer in the field of material handling. Designed to streamline operations, enhance efficiency, and facilitate seamless processes, this ingenious technology has found a significant place across various industries. With its versatility and multifunctionality, the system is gaining rapid popularity, particularly in the food industry and in conjunction with packaging machines. In this article, we will delve into the core aspects of the multi-outlet bucket conveyor system, exploring its applications, functionality, and the multitude of benefits it offers.

Applications in the Food Industry

The food industry is one of the most dynamic and rapidly evolving sectors globally. Consumer demand for quality, safety, and efficiency in food production has driven manufacturers to seek innovative solutions to meet these expectations. The multi-outlet bucket conveyor system has emerged as a pivotal tool in addressing these challenges.

With the capacity to transport a wide variety of food products including grains, pulses, cereals, frozen foods, and more, this conveyor system ensures gentle handling to prevent product damage. In addition to minimizing product loss, it also maintains hygiene standards, a crucial factor in the food industry. Whether transferring products from processing stations to packaging areas or from packaging to palletization, the multi-outlet bucket conveyor system ensures a seamless transition, reducing the risk of contamination.

Integration with Packaging Machines

The synergy between the multi-outlet bucket conveyor system and packaging machines underscores its importance in modern manufacturing processes. Packaging is not just about containment; it's about preserving the integrity of the product, enhancing shelf appeal, and complying with safety standards. This conveyor system complements packaging machines by ensuring a consistent flow of materials to the packaging unit.

Consider a scenario where a snack manufacturing facility is packaging different flavors of chips into individual pouches. The multi-outlet bucket conveyor system efficiently segregates these flavors into separate outlets, which are then fed directly into the respective packaging machines. This eliminates the need for manual sorting and reduces the risk of cross-contamination. As a result, the system not only enhances operational efficiency but also upholds the quality and safety of the final product.

How It Works

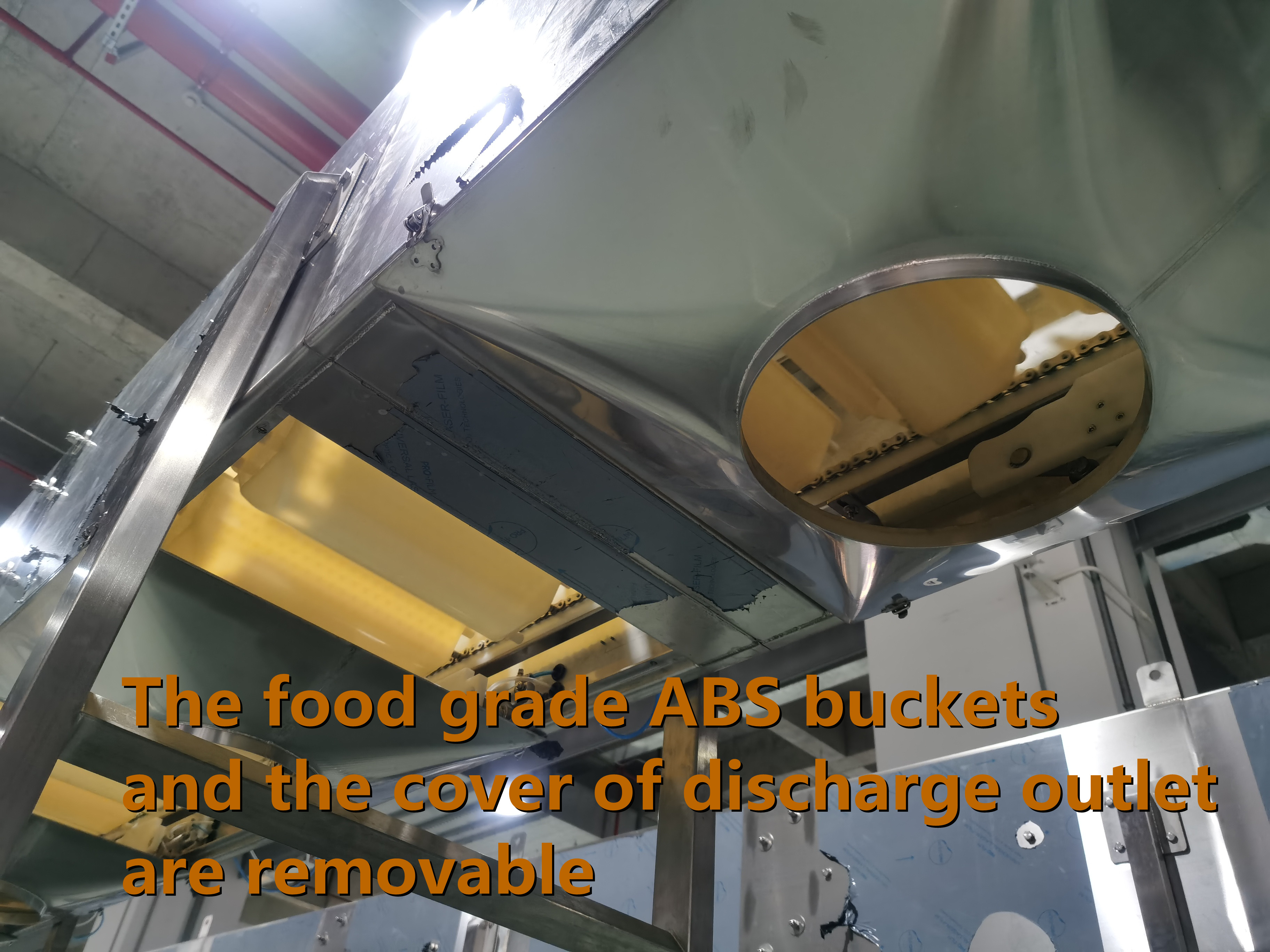

At its core, the multi-outlet bucket conveyor system operates on a simple yet effective principle. The system consists of a series of buckets or containers attached to a moving conveyor belt. These buckets are strategically designed to accommodate the specific product and prevent spillage during transportation. The conveyor belt moves continuously, allowing the buckets to carry the materials from one point to another.

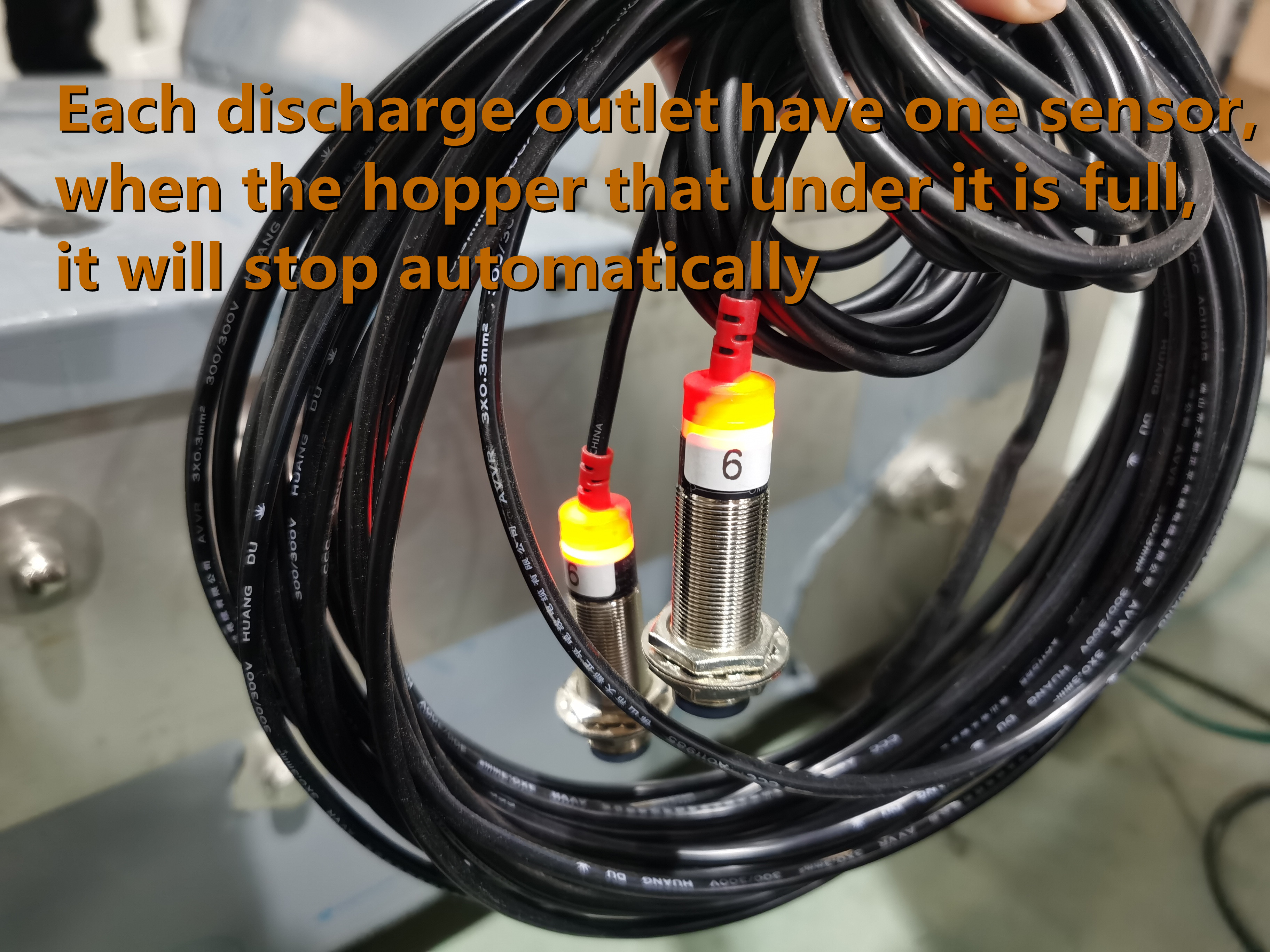

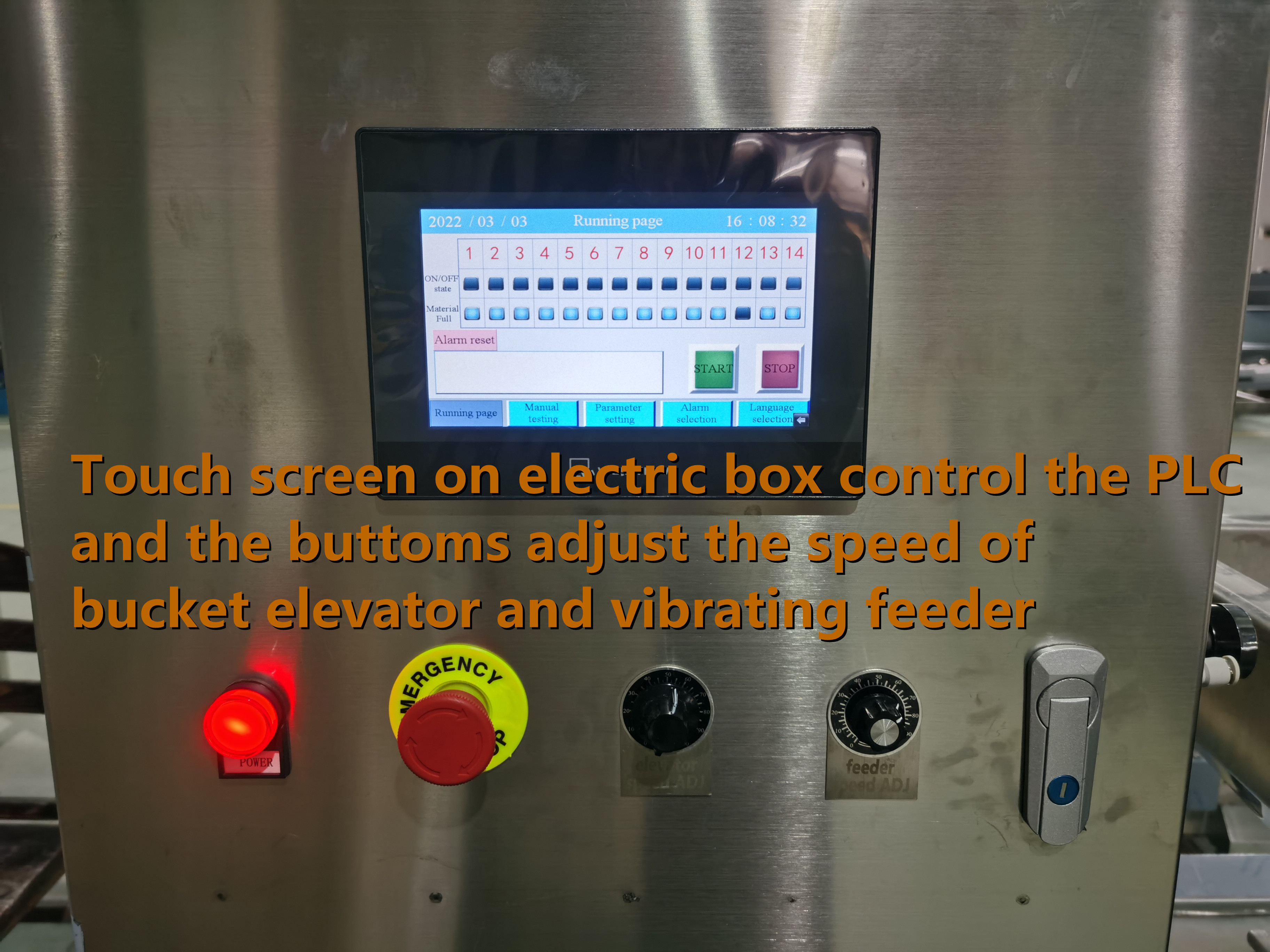

The key differentiator is the system's ability to divert the flow of materials to multiple outlets based on predefined parameters. This is achieved through intelligent sensors, actuators, and control systems. These components work in tandem to detect the type of product, its quantity, and destination, thus ensuring accurate diversion. The adaptability of the system is its hallmark, as it can be programmed to handle a diverse range of products and packaging requirements.

Benefits of the Multi-Outlet Bucket Conveyor System

-

Enhanced Efficiency: One of the most significant advantages of this system is the marked improvement in operational efficiency. The automation of material handling reduces the reliance on manual labor, minimizing errors and ensuring a consistent flow of materials.

-

Product Integrity: The gentle handling ensured by the bucket conveyor system prevents product damage, preserving the quality, appearance, and integrity of the items being transported. This is crucial, especially in the food industry where consumer satisfaction is directly linked to the product's condition upon purchase.

-

Hygiene and Safety: Maintaining hygiene and safety standards is paramount in the food industry. The system's automated operation reduces the risk of contamination by minimizing human contact with the products.

-

Customization: The adaptability of the multi-outlet bucket conveyor system is a major advantage. It can be tailored to accommodate various product types, sizes, and packaging requirements. This versatility makes it an ideal choice for businesses dealing with diverse product lines.

-

Cost Savings: While the initial investment may seem substantial, the long-term benefits of reduced labor costs, increased production efficiency, and minimized product loss make the system a cost-effective choice.

Conclusion

The multi-outlet bucket conveyor system has ushered in a new era of efficiency, precision, and flexibility in material handling. With its applications in the food industry and seamless integration with packaging machines, it addresses some of the most pressing challenges in modern manufacturing. As industries continue to evolve and seek innovative solutions, this conveyor system stands as a testament to human ingenuity and engineering prowess, reshaping the way materials are handled, processed, and packaged.