Pendulum Bucket Conveyor: Specialized Solutions For Bulk Material

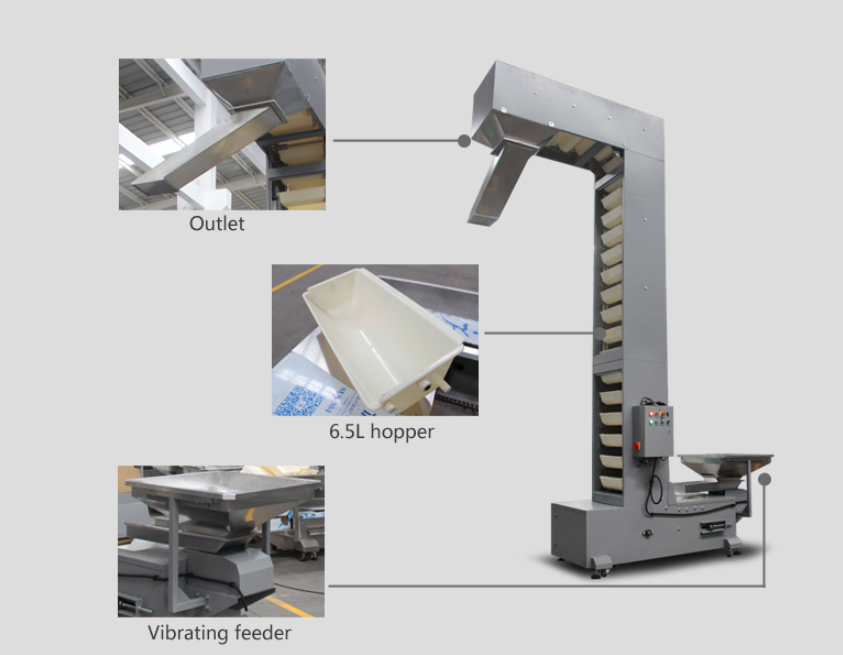

The pendulum bucket conveyor is the specialized solution for you to ship the bulk materials from one or multiple feed points to a central discharge with high capacity. Pendulum conveyor can be used to transport a wide range of free-flowing materials in the food, agriculture, chemical industry, such as confectionery, peanut, rice, powder, and other granules. In this article, we will walk through the benefits of a pendulum bucket elevator.

All parts have easy-to-remove inspection covers and a conveniently located inspection window. Moreover, the buckets are resistant to high temperatures.

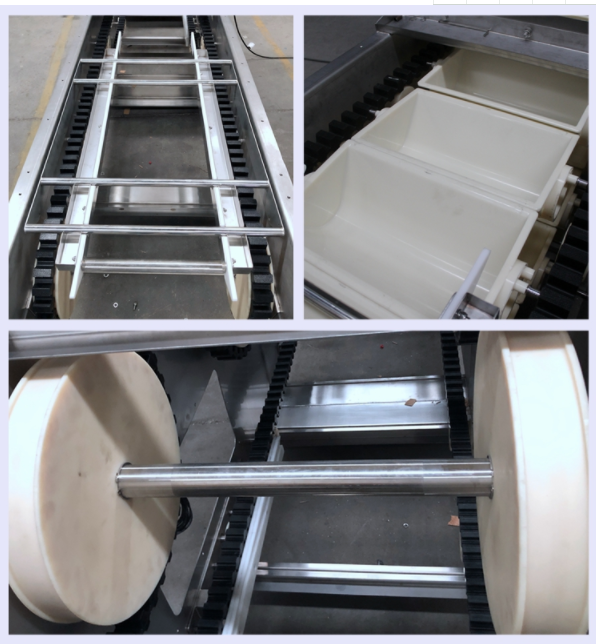

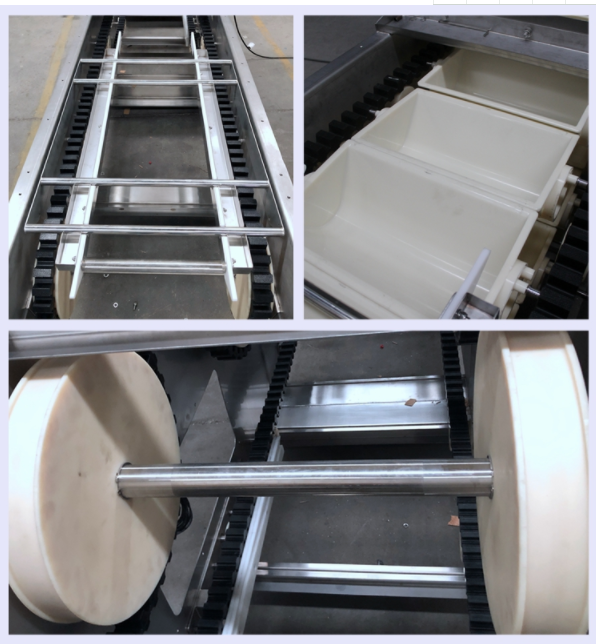

Two neighboring buckets are connected by a flexible connecting flap. Thus there is no gap between buckets, which guarantees the material cannot trickle down between the buckets.

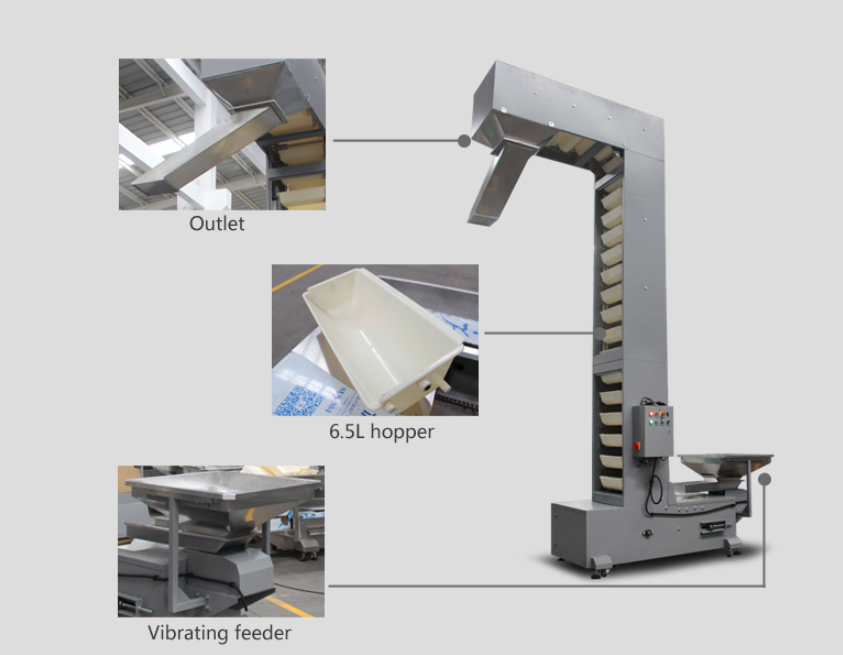

The bucket of the pendulum conveyor will swing slightly during the ascent process, which is convenient for the material to fall, which helps to improve the transportation speed.

Customized T Shape Pendulum Bucket Conveyor with Two Feeding Sides

● Easy to disassemble and clean

The buckets of the pendulum conveyor are independent, and you can easily remove the hopper and clean them. And the buckets have a quick-release mechanism to facilitate this process.All parts have easy-to-remove inspection covers and a conveniently located inspection window. Moreover, the buckets are resistant to high temperatures.

● Spillage-free and efficient operation

Two neighboring buckets are connected by a flexible connecting flap. Thus there is no gap between buckets, which guarantees the material cannot trickle down between the buckets.

The bucket of the pendulum conveyor will swing slightly during the ascent process, which is convenient for the material to fall, which helps to improve the transportation speed.

● Multiple choices:

Our pendulum conveyor has several outlets to satisfy different application scenes. Also, according to the shape, we have c type and z type conveyor to choose.

Parameter of z type bucket elevator conveyor :

| Model | FM-3B3 Bucket conveyor |

| Bucket Volume | 1.0L/1.8L/3.8L/6.5L |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | 2-3.5m³/h / 4-6m³/h / 6.5-8m³/h / 8.5-12m³/h |

| Machine Height | 3296mm for standard (1.8L) |

| Discharging Height | 3256mm for standard (1.8L) |

| Hopper Material | Food grade PP, ABS, Stainless steel |

| Packing Size | 2050mmX1350mmX980mmfor standard (1.8L) |

| Voltage | AC220V or three phase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

● High Speed Transportation Speed:

This pendulum bucket conveyor has an efficient conveying speed and the speed can be up to 30m3/h. And all elevators are equipped with an automatic chain tension device and built-in overload protection.● Sanitary design:

The pendulum bucket conveyor adopts the design of dust-tight construction, which ensures no contamination from the surrounding environment. Also, the Internal and external of the machine is also very smooth, and there is nowhere for dust to hide.

Parameter of C Type Bucket Elevator:

| Model | FM-3B3 Bucket elevator |

| Bucket Volume | 1.0L/1.8L/3.8L/6.5L |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | 2-3.5m³/h / 4-6m³/h / 6.5-8m³/h / 8.5-12m³/h |

| Machine Height | 3296mm for standard (1.8L) |

| Discharging Height | 3256mm for standard (1.8L) |

| Hopper Material | Food grade PP, ABS, Stainless steel |

| Packing Size | 2050mmX1350mmX980mmfor standard (1.8L) |

| Voltage | AC220V or three phase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

● Gentle feeding:

The conveyed materials fall from the hopper under the influence of gravity instead of being ejected, which avoids the damage and degradation of the materials.

Customized T Shape Pendulum Bucket Conveyor with Two Feeding Sides

● Rubber block chain:

This pendulum bucket conveyor is equipped with rubber block chain, and it shines low noise, corrosion-free, lubrication-free, high tensile strength, wear resistance, and maintenance-free operation.Application: