Maintenance Tips for Gravity Roller Conveyor System

Gravity roller conveyors are an essential tool for material handling in a variety of industries, including manufacturing, logistics, and warehousing. These conveyor systems use gravity to move items along the conveyor line, making them a cost-effective and efficient solution for transporting items over short distances.

Gravity Roller Conveyor vs. Powered Roller Conveyor

While gravity roller conveyors are a popular choice for businesses looking for a cost-effective and efficient material handling solution, they are not suitable for all applications. Powered roller conveyors, which use motors to move items along the conveyor line, are better suited for transporting heavier items over longer distances. However, powered roller conveyors are typically more expensive and require more maintenance than gravity roller conveyors.

How Gravity Roller Conveyors Work

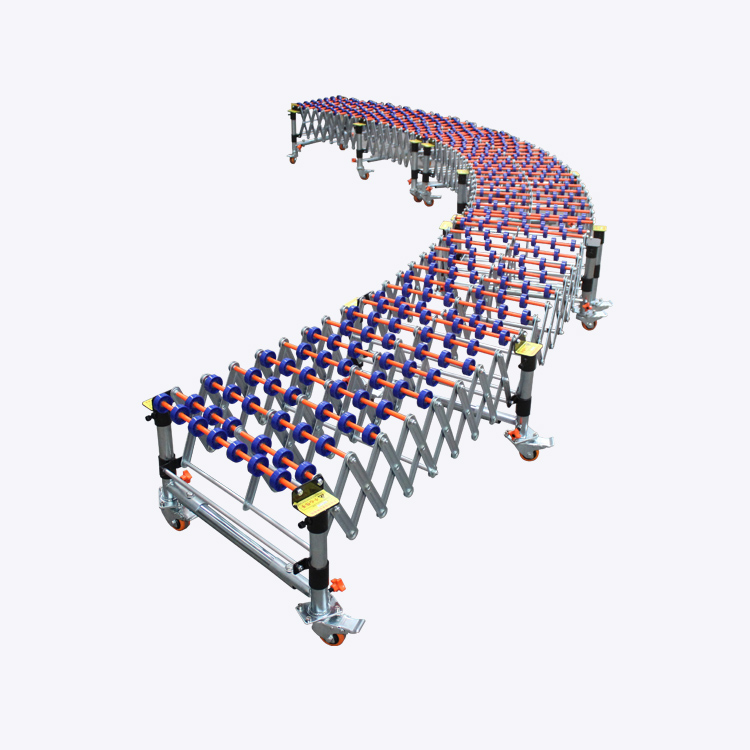

Gravity roller conveyors consist of a series of roller bearings that allow items to move along the conveyor line under the force of gravity. The conveyor rollers are mounted on axles and are free to rotate, allowing items to move along the conveyor line with minimal friction. There are several types of gravity roller conveyors, including straight, curved, and spiral conveyors.

Advantages of Gravity Roller Conveyors

One of the main advantages of gravity roller conveyors is their efficiency and cost-effectiveness. Since they rely on gravity to move items along the conveyor line, they do not require electricity or other external power sources. They are also highly versatile, with the ability to transport a wide range of items of different sizes and shapes. Finally, gravity roller conveyors are low maintenance, requiring minimal upkeep and repair.

Gravity Roller Conveyor vs. Powered Roller Conveyor

While gravity roller conveyors are a popular choice for businesses looking for a cost-effective and efficient material handling solution, they are not suitable for all applications. Powered roller conveyors, which use motors to move items along the conveyor line, are better suited for transporting heavier items over longer distances. However, powered roller conveyors are typically more expensive and require more maintenance than gravity roller conveyors.

How Gravity Roller Conveyors Work

Gravity roller conveyors consist of a series of roller bearings that allow items to move along the conveyor line under the force of gravity. The conveyor rollers are mounted on axles and are free to rotate, allowing items to move along the conveyor line with minimal friction. There are several types of gravity roller conveyors, including straight, curved, and spiral conveyors.

Advantages of Gravity Roller Conveyors

One of the main advantages of gravity roller conveyors is their efficiency and cost-effectiveness. Since they rely on gravity to move items along the conveyor line, they do not require electricity or other external power sources. They are also highly versatile, with the ability to transport a wide range of items of different sizes and shapes. Finally, gravity roller conveyors are low maintenance, requiring minimal upkeep and repair.

Maintenance Tips for Gravity Roller Conveyors

Regular maintenance is essential for ensuring the optimal performance and longevity of gravity roller conveyors. Here are some tips for keeping your gravity roller conveyor system running smoothly.

Regular cleaning and inspection: Dirt, debris, and other contaminants can accumulate on the conveyor line over time, leading to increased friction and wear on the conveyor rollers. Regular cleaning and inspection can help prevent these issues and extend the life of your conveyor system.

Lubrication of roller bearings: Proper lubrication of the roller bearings is crucial for ensuring smooth operation of the conveyor line. Apply lubricant to the roller bearings at regular intervals, following the manufacturer's recommended guidelines.

Replacement of worn components: Over time, the conveyor rollers and other components of the system may become worn or damaged. Replace any worn or damaged components as soon as possible to prevent further damage to the conveyor line.

Regular cleaning and inspection: Dirt, debris, and other contaminants can accumulate on the conveyor line over time, leading to increased friction and wear on the conveyor rollers. Regular cleaning and inspection can help prevent these issues and extend the life of your conveyor system.

Lubrication of roller bearings: Proper lubrication of the roller bearings is crucial for ensuring smooth operation of the conveyor line. Apply lubricant to the roller bearings at regular intervals, following the manufacturer's recommended guidelines.

Replacement of worn components: Over time, the conveyor rollers and other components of the system may become worn or damaged. Replace any worn or damaged components as soon as possible to prevent further damage to the conveyor line.

Conclusion

Gravity roller conveyors are a versatile and cost-effective solution for material handling in a variety of industries. By understanding how these conveyor systems work and implementing proper maintenance practices, businesses can optimize the performance and longevity of their conveyor systems, improving overall productivity and efficiency.