How does a belt conveyor work?

Belt onveyor system consists of a belt stretched across two or more pulleys. The most common conveyor system designs use a rotor to power the drive pulley and belt. The belt forms a closed loop around the pulleys so it can continually rotate. One pulley, known as the drive pulley, drives or tows the belt, moving items from one location to another.

Usually the belt is manufactured from several layers of material. The belt or conveyor surface belting itself is available in a wide range of materials, such as plastic, leather, rubber, and also coated fabric.

Inclined Conveyor

Inclined belt conveyor systems are used when products must be transported upwards. A Basic incline belt conveyor work by incorporating two rollers, one being an idler pulley and another being a powered pulley. These rollers are then set into a solid frame typically made from steel, stainless steel, or aluminum profile.

Inclined belt conveyor is used to bring products from one level to another via a hinged or flexible belt. Products can be controlled by cleats of cleated belt conveyor during elevation, and kept on the belt by flights or side rail systems. A conveyor belt can be provided with carriers or high-friction belt material to ensure that the products do not roll down or slide.

APPLICATIONS: These systems can cross over with cleated belt conveyors to transport products to different elevations while keeping them from falling off the line. Aside from transferring objects between floors, these conveyor belts are also suitable for boosting gravity flow systems.

Let’s watch a video to learn how does inclined conveyor work

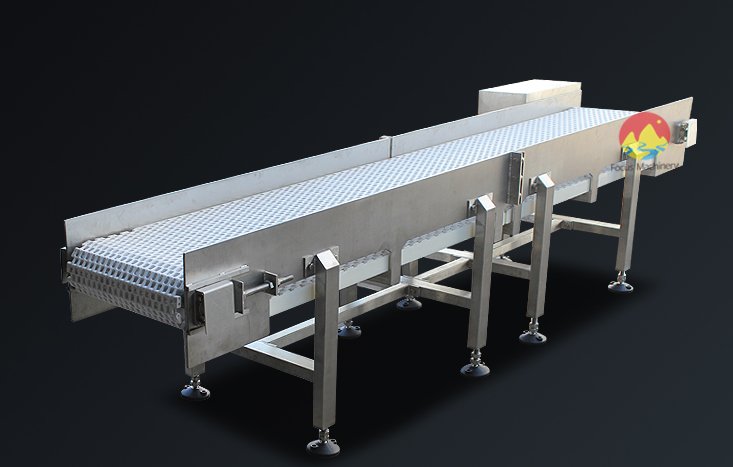

Flat conveyor

Flat belts are useful for internal conveyance, i.e. transporting items within a facility. This type of conveyor belt uses a series of powered pulleys to move a continuous flat belt, which can consist either of natural material or synthetic fabric. Items are placed on top of the moving belt and carried from one end to the other. To align a flat belt conveyor simply adjust the tail end pulley or the idler pulley, it is provided with adjuster bolt to adjust it in order to align the conveyor.

Since its belts can be made of different kinds of materials, this type of conveyor belt is incredibly versatile. Flat belt conveyors are best suited for handling cartoons, bags, sorting and picking component range, filing, labeling, inspection, packaging and wrapping tasks.

APPLICATIONS: Flat belt systems are often the conveyor of choice for industrial environments, wash down areas, and slow assembly lines. Fitted with the right belt, it can also convey small, soft, or irregularly shaped items without damaging them.

Let’s watch a video to learn how does inclined conveyor work