Enhancing Material Handling Efficiency: Exploring the Benefits of Rubber Chain Bucket Elevators

Introduction

In the realm of material handling, efficient and reliable elevators play a crucial role in ensuring smooth operations and maximizing productivity. Among the various types of elevators available, rubber chain bucket elevators have gained significant popularity due to their unique features and advantages. In this article, we will delve into the importance of dust-tight operation and ATEX compliance, as well as explore the key differences between rubber chain bucket elevators and ordinary steel chain bucket elevators. We will also discuss the different types of rubber chain bucket elevators and the benefits they offer in material handling processes.

- Dust-Tight Operation: Ensuring Safety and Environmental Protection

Dust containment is a critical consideration in many industries, particularly those handling fine powders or dusty materials. Rubber chain bucket elevators are designed to provide a dust-tight operation, preventing the release of dust particles into the surrounding environment. This feature offers several important benefits:

a. Safety: Dust particles generated during material handling can pose serious health and safety hazards to workers. Inhalation of airborne particles can lead to respiratory issues and long-term health problems. By effectively containing dust, rubber chain bucket elevators create a safer working environment, reducing the risk of occupational hazards.

b. Environmental Protection: Dust emissions can also have adverse effects on the environment, contributing to air pollution and potentially contaminating nearby ecosystems. Rubber chain bucket elevators mitigate these risks by preventing dust from escaping, ensuring compliance with environmental regulations and fostering sustainability.

Statistics:

- According to the Occupational Safety and Health Administration (OSHA), exposure to harmful dust is a major cause of occupational lung diseases, affecting millions of workers worldwide.

- A study by the World Health Organization (WHO) estimates that occupational exposure to airborne particulate matter results in approximately 400,000 premature deaths each year.

- ATEX Compliance: Addressing Explosive Atmospheres

Certain industries, such as food processing, pharmaceuticals, and chemicals, require equipment that complies with ATEX (ATmosphères EXplosibles) directives. ATEX compliance ensures that the equipment can safely operate in potentially explosive atmospheres where combustible gases, vapors, or dust are present. Rubber chain bucket elevators offer inherent advantages in ATEX compliance:

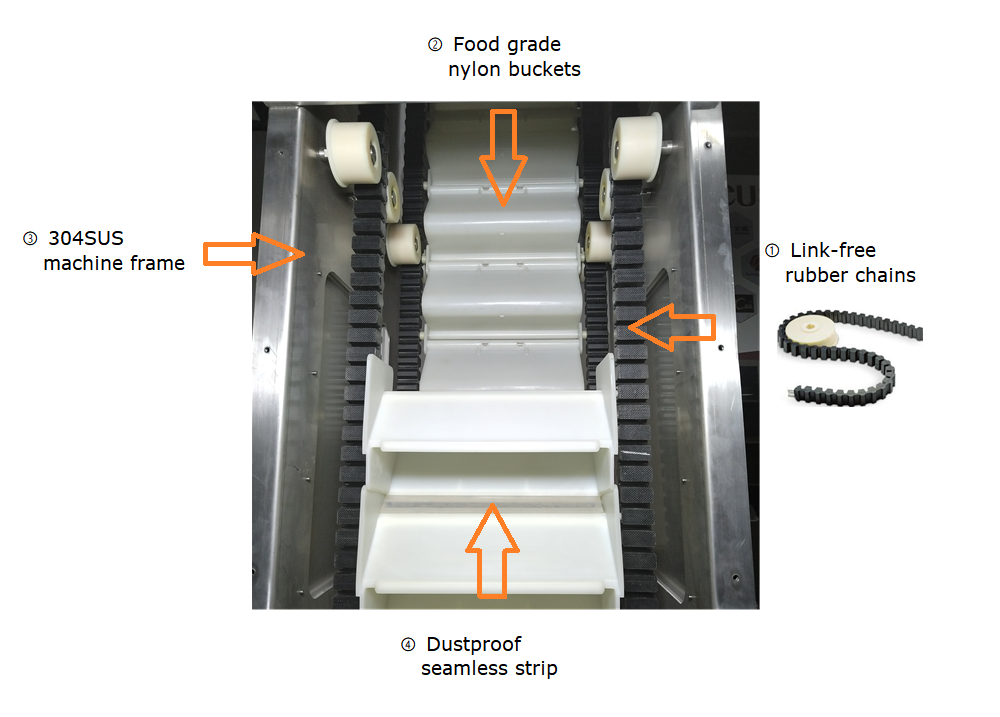

a. Non-Sparking Design: Rubber chain bucket elevators incorporate non-sparking materials, such as rubberized chains and buckets, minimizing the risk of ignition in explosive environments. This reduces the likelihood of accidents caused by sparks, which could ignite flammable substances.

b. Static Dissipation: Rubberized components possess excellent anti-static properties, dissipating any electrical charges that may accumulate during operation. This feature prevents the build-up of static electricity, reducing the chances of ignition in environments with combustible materials.

Examples:

- In a chemical manufacturing plant, a rubber chain bucket elevator was installed to handle explosive powders. Its ATEX compliance ensured safe operation in the presence of potentially flammable dust, eliminating the risk of explosions and enhancing worker safety.

- Rubber Chain Bucket Elevator vs. Ordinary Steel Chain Bucket Elevator: Key Differences

Rubber chain bucket elevators differ significantly from ordinary steel chain bucket elevators in their design and performance. Understanding these differences can help make informed decisions when choosing the right elevator for specific material handling requirements. Here are some differentiating factors:

a. Noise Reduction: Rubber chain bucket elevators operate with reduced noise levels compared to steel chain elevators. The rubberized components dampen vibrations and minimize metal-to-metal contact, resulting in quieter operation. This is particularly beneficial in environments where noise control is a priority, such as residential areas near industrial facilities.

b. Improved Impact Resistance: Rubberized chains and buckets offer superior impact resistance compared to their steel counterparts. This ensures smoother operation, minimizes damage to the elevator components, and extends their service life. The enhanced impact resistance of rubber chain bucket elevators is especially advantageous in handling abrasive or heavy materials.

c. Enhanced Belt Traction: Rubber chain bucket elevators utilize a rubber belt or chain, which provides excellent traction and prevents slippage. This ensures reliable and efficient material transportation, even when dealing with steep inclines or heavy loads. Steel chain bucket elevators, on the other hand, may be prone to slippage under similar conditions, leading to decreased productivity and potential material spillage.

- Benefits of Rubber Chain Bucket Elevators

1. Increased Equipment Longevity: The impact-resistant nature of rubberized components minimizes wear and tear, prolonging the lifespan of the elevator. This reduces maintenance costs and downtime associated with component replacements.

2. Enhanced Efficiency: The improved traction of rubber belts/chains and the ability to handle heavy loads ensure efficient material transportation, optimizing overall operational efficiency.

3. Versatile Application: Rubber chain bucket elevators can be used in various industries, including agriculture, mining, cement, and recycling. Their flexibility allows for handling a wide range of materials, from fine powders to larger particles.

4. Lower Energy Consumption: The reduced friction between rubber components results in lower energy consumption compared to steel chain elevators. This translates into cost savings and increased energy efficiency.

Conclusion

Rubber chain bucket elevators provide numerous advantages over ordinary steel chain elevators, making them an ideal choice for industries where dust containment, ATEX compliance, noise reduction, and impact resistance are paramount. Their ability to ensure a dust-tight operation, comply with ATEX directives, and offer improved performance and longevity make them a valuable asset in material handling processes. By choosing rubber chain bucket elevators, industries can enhance safety, protect the environment, and improve overall operational efficiency.

Sources:

- Occupational Safety and Health Administration (OSHA)

- World Health Organization (WHO)

- ATEX Directive (2014/34/EU)

- "Dust Emission and Explosion Control Methods for Rubber Conveyor Belting in Bulk Material Handling" by Janusz Niedbała