How to Calculate Bucket Elevator Capacity

Focusconveyor Bucket Elevator is mainly used for food, crops, pharmaceuticals and chemical products with good fluidity. Such as potato chips, peanuts, candy, dried fruit, frozen food, vegetables, chemicals and other granular or block products, the materials are vertically transported from low to high.

The hopper of the horizontal bucket conveyor is the load-bearing part, most of which are welded or stamped from steel plates with a thickness of 2-6 mm. Welding an additional lip to the outer lip of the hopper can greatly reduce hopper lip wear. Due to the characteristics of the material and the method of loading and unloading.

Differently, the hoppers are divided into three types: deep buckets, shallow buckets and sharp-edged surface buckets with guide grooves. We mentioned above that the deep hopper is a triangular-shaped hopper with guiding sides, which are placed one by one on the elevator. When the material is unloaded, the two ends of the front material hopper and the front wall will form the next hopper. Unload the guide channel.

The deep bucket is suitable for the transportation of heavier semi-abrasive materials or bulky materials with relatively large abrasiveness. The speed of the deep bucket will be relatively low, and it is also based on the effect of gravity. After reaching a certain height, it is tilted and unloaded. expected.

The common bucket elevator conveyor systems in China use deep buckets and shallow buckets, and there are also those with guide grooves. When the raw cement and clinker are put into storage, because the nature of the material is dry and loose, and the state is bulk or powder, most of them use deep buckets.

Centrifugal unloading bucket elevator hopper distance selection must abide by the following criteria: the material thrown from the hopper during unloading cannot catch up with the hopper walking in front, so as to avoid the material hitting the front during unloading as much as possible The phenomenon of returning material caused by the hopper.

1. The hopper is made of food-grade polypropylene (PP) material, which has the characteristics of beautiful appearance, not easy to deform, and resistant to high temperature and low temperature.

2. The chain bucket elevator can perfectly realize continuous or intermittent conveying and can be matched with other feeding equipment.

3. The chain bucket elevator is easy to assemble and disassemble, and the hopper is easy to clean.

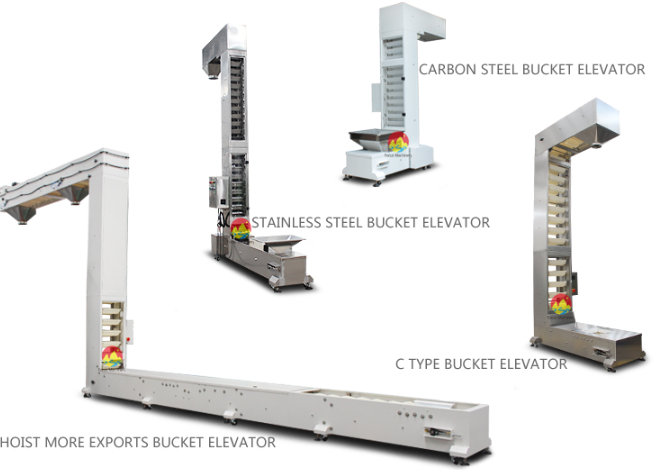

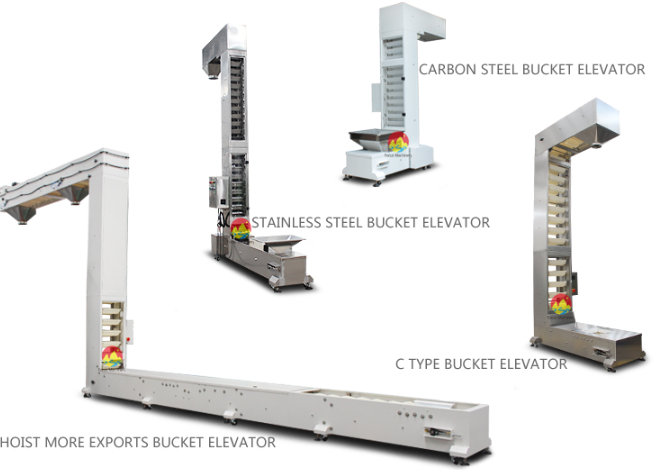

1. Carbon steel.

2. Multiple outlets.

Hoppers are available in 1L bucket (2-3.5m³/H), 1.8L bucket (3.5-6m³/H), 3.8L bucket (6-8m³/H), 6.5L bucket (8-12m³/H), and the material is also It can be made of food-grade ABS material, with yellowish color and higher hardness, suitable for large-capacity buckets, conventional 1L, 3.8L are pattern buckets, 1.8L, 6.5L are smooth buckets, and can also be customized according to requirements

z type bucket elevator video

The hopper of the horizontal bucket conveyor is the load-bearing part, most of which are welded or stamped from steel plates with a thickness of 2-6 mm. Welding an additional lip to the outer lip of the hopper can greatly reduce hopper lip wear. Due to the characteristics of the material and the method of loading and unloading.

Differently, the hoppers are divided into three types: deep buckets, shallow buckets and sharp-edged surface buckets with guide grooves. We mentioned above that the deep hopper is a triangular-shaped hopper with guiding sides, which are placed one by one on the elevator. When the material is unloaded, the two ends of the front material hopper and the front wall will form the next hopper. Unload the guide channel.

The deep bucket is suitable for the transportation of heavier semi-abrasive materials or bulky materials with relatively large abrasiveness. The speed of the deep bucket will be relatively low, and it is also based on the effect of gravity. After reaching a certain height, it is tilted and unloaded. expected.

The common bucket elevator conveyor systems in China use deep buckets and shallow buckets, and there are also those with guide grooves. When the raw cement and clinker are put into storage, because the nature of the material is dry and loose, and the state is bulk or powder, most of them use deep buckets.

Centrifugal unloading bucket elevator hopper distance selection must abide by the following criteria: the material thrown from the hopper during unloading cannot catch up with the hopper walking in front, so as to avoid the material hitting the front during unloading as much as possible The phenomenon of returning material caused by the hopper.

Product performance:

1. The hopper is made of food-grade polypropylene (PP) material, which has the characteristics of beautiful appearance, not easy to deform, and resistant to high temperature and low temperature.

2. The chain bucket elevator can perfectly realize continuous or intermittent conveying and can be matched with other feeding equipment.

3. The chain bucket elevator is easy to assemble and disassemble, and the hopper is easy to clean.

Optional:

1. Carbon steel.

2. Multiple outlets.

According to customer drawings, special customized

Hoppers are available in 1L bucket (2-3.5m³/H), 1.8L bucket (3.5-6m³/H), 3.8L bucket (6-8m³/H), 6.5L bucket (8-12m³/H), and the material is also It can be made of food-grade ABS material, with yellowish color and higher hardness, suitable for large-capacity buckets, conventional 1L, 3.8L are pattern buckets, 1.8L, 6.5L are smooth buckets, and can also be customized according to requirements

z type bucket elevator video