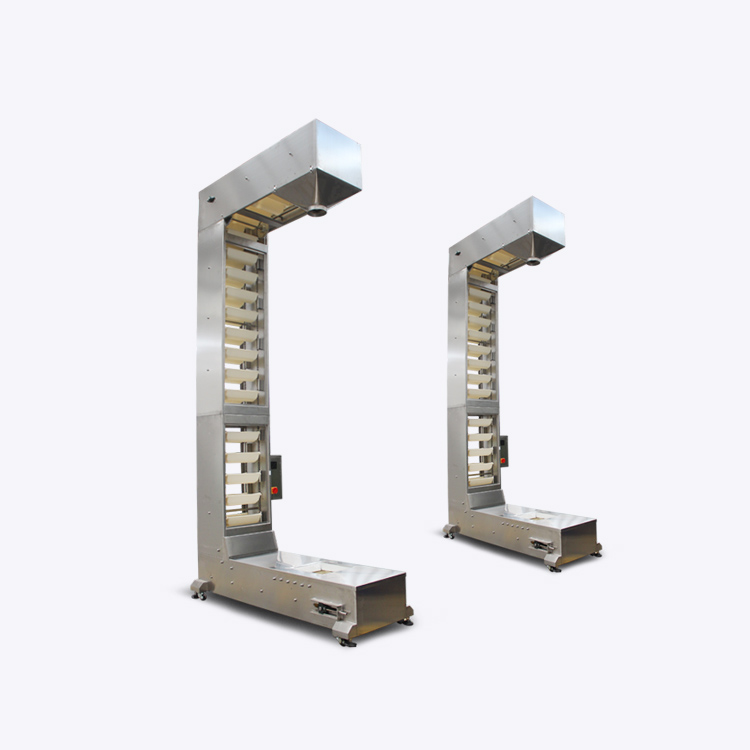

C Type Bucket Elevator VS Z Type Bucket Conveyor

The continuous bucket conveyor is a type of bucket elevator designed to transport products gently and without degradation between processes, resulting in a continuous "bucket belt" or bucket conveyor. And the Z type bucket conveyor and the C type bucket elevator are two common types of continuous bucket elevators. However, Z type bucket conveyor or C type bucket elevator: which is better?

Z type bucket elevator is suitable for conveying all kinds of powder and granular materials, especially for non-sticky materials - fully enclosed, with no leakage and no pollution. The advantage of the Z type bucket elevator conveyor is its flexible composition and very low material damage rate.

2. The vertical bucket elevator allows for controlled feeds at one or more locations and can easily interface with various feeding devices.

3. All parts have easy-to-remove inspection covers and a conveniently located inspection window. The buckets have a quick-release mechanism to facilitate fast installation or removal of buckets. All elevators are equipped with an automatic chain tension device and built-in overload protection.

(2) Single or multiple discharges

(3) Anywhere in the circuit available

(4) Make as per the client's requirements

Designed for heavy-duty operation and long life, the C type bucket elevator is ideal for industrial applications. The incoming product is fed continuously and very gently into the continuous bucket conveyor by means of a vibratory feeder. The C type bucket elevator can also handle large horizontal distances and can replace a combination of belt conveyors and regular bucket elevators.

Focus Machinery is a professional continuous bucket elevator manufacturer and supplier in China, offering top-quality Z type bucket conveyors and C type bucket elevators for various industries. Please feel free to contact us at sales@focusmachinery.com for more details!

What Is The Continuous Bucket Conveyor?

The continuous bucket conveyor operates at speeds between 1 and 250 feet per minute, which rely on gravity to discharge material from their buckets. The bucket is designed to be inclined as they run from the overhead pulley to the down leg, allowing the material being transported to pour out of the bucket at a natural speed.What Are The Purposes Of The Continuous Bucket Elevator?

The continuous bucket elevator is for the vertical transport of bulk and small grain-size materials, allowing transporting material without spillage and contamination. And the bucket elevator design of the enclosed conveyor is to prevent dust.Z Type Bucket Elevator Conveyor

Z type bucket conveyor, as the name implies, is Z-shaped to convey materials by several buckets suspended from a chain. The Z type bucket elevator conveyor can convey materials horizontally - vertically – horizontally. And can be fed through single or multiple inlets and finished discharging through multiple discharge ports/outlets.Z type bucket elevator is suitable for conveying all kinds of powder and granular materials, especially for non-sticky materials - fully enclosed, with no leakage and no pollution. The advantage of the Z type bucket elevator conveyor is its flexible composition and very low material damage rate.

Features

1. The buckets are made of food-grade reinforced polypropylene, molded in one piece, and can handle temperatures from -10 to 60 degrees Fahrenheit.2. The vertical bucket elevator allows for controlled feeds at one or more locations and can easily interface with various feeding devices.

3. All parts have easy-to-remove inspection covers and a conveniently located inspection window. The buckets have a quick-release mechanism to facilitate fast installation or removal of buckets. All elevators are equipped with an automatic chain tension device and built-in overload protection.

Discharge Options

(1) Over the end discharge(2) Single or multiple discharges

(3) Anywhere in the circuit available

(4) Make as per the client's requirements

C Type Bucket Elevator

The C type bucket elevator is designed to lift a wide variety of materials, capable of very gentle vertical transport of various granular products, conveying grain and fine dry materials to the position at the top of the machine. However, the C type bucket elevator is not suitable for materials that have an adhesive, biting, or corrosive effect on metal machine parts.Designed for heavy-duty operation and long life, the C type bucket elevator is ideal for industrial applications. The incoming product is fed continuously and very gently into the continuous bucket conveyor by means of a vibratory feeder. The C type bucket elevator can also handle large horizontal distances and can replace a combination of belt conveyors and regular bucket elevators.

| Model | FM-3B3 Bucket elevator |

| Bucket Volume | 1.0L/1.8L/3.8L/6.5L |

| Machine Structure | Stainless steel or carbon steel |

| Production Capacity | 2-3.5m³/h / 4-6m³/h / 6.5-8m³/h / 8.5-12m³/h |

| Machine Height | 3296mm for standard (1.8L) |

| Discharging Height | 3256mm for standard (1.8L) |

| Hopper Material | Food grade PP, ABS, Stainless steel |

| Packing Size | 2050mmX1350mmX980mmfor standard (1.8L) |

| Voltage | AC220V or three phase 380V, 50hz/60hz |

| Power Supply | 0.75kw |

Conclusion

The continuous bucket conveyor is mainly used for feeding weighing and packaging machines or color sorting machines. And it is also perfect for cycle loading and unloading of automated production lines.Focus Machinery is a professional continuous bucket elevator manufacturer and supplier in China, offering top-quality Z type bucket conveyors and C type bucket elevators for various industries. Please feel free to contact us at sales@focusmachinery.com for more details!