Bucket Elevator Conveyor: A Guide to Vertical Bulk Material Handling

If you work in the agriculture, mining, or manufacturing industries, you may have heard of a bucket elevator conveyor. This type of vertical conveyor is commonly used for moving bulk materials from one level to another. In this guide, we will cover everything you need to know about bucket elevator conveyors, including types, advantages, design considerations, maintenance, safety, and applications.

Continuous bucket elevator: This type of elevator uses a continuous chain or belt to move the buckets. It is suitable for handling abrasive or sluggish materials.

Positive discharge bucket elevator: This type of elevator uses a discharge mechanism to empty the buckets completely. It is ideal for handling materials that tend to stick or clump together.

Efficiency: Bucket elevator conveyors can move materials quickly and efficiently, reducing the need for manual labor and increasing throughput.

Versatility: Bucket elevator conveyors can handle a wide range of materials, including fine powders, bulky grains, and abrasive materials.

Space-saving: Bucket elevator conveyors have a small footprint, making them ideal for use in facilities with limited space.

Lift height: The distance between the top and bottom of the elevator will affect the design of the conveyor, including the size and spacing of the buckets, the strength of the chains or belts, and the power of the drive unit.

Throughput: The desired throughput will affect the design of the conveyor, including the speed of the conveyor, the size and shape of the buckets, and the power of the drive unit.

What is a bucket elevator conveyor?

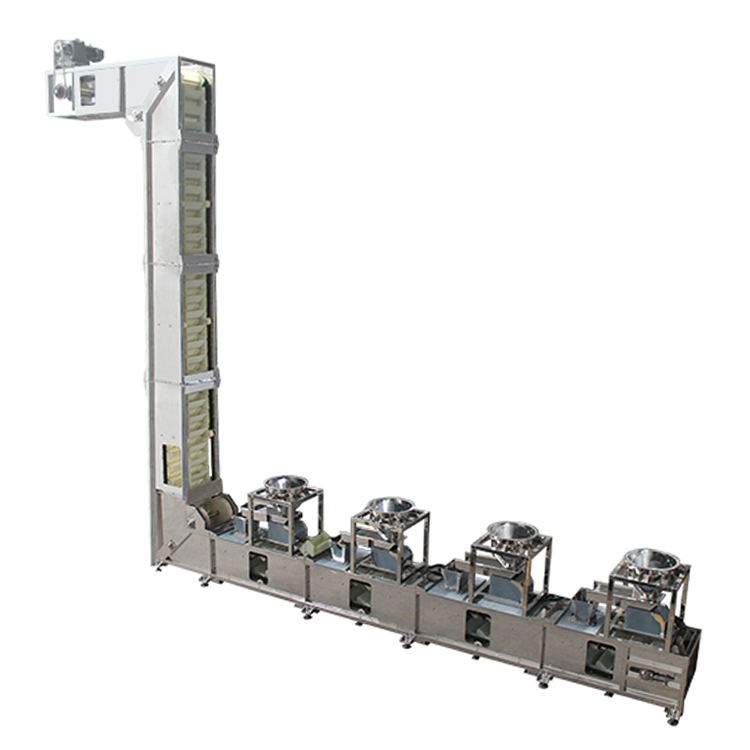

A bucket elevator conveyor is a type of vertical conveyor that uses buckets attached to a rotating chain or belt to move bulk materials vertically. The buckets scoop up the material from a lower level and deposit it at a higher level, where it can be unloaded or further processed. Bucket elevator conveyors are used in a variety of industries for handling materials such as grains, seeds, minerals, and chemicals.Types of bucket elevator conveyors

Centrifugal bucket elevator: This type of elevator uses centrifugal force to discharge materials from the buckets. It is ideal for handling fine and lightweight materials with a high throughput.Continuous bucket elevator: This type of elevator uses a continuous chain or belt to move the buckets. It is suitable for handling abrasive or sluggish materials.

Positive discharge bucket elevator: This type of elevator uses a discharge mechanism to empty the buckets completely. It is ideal for handling materials that tend to stick or clump together.

Advantages of using a bucket elevator conveyor

Vertical transport: Bucket elevator conveyors can move materials vertically, which is useful when you need to transfer materials between different levels.Efficiency: Bucket elevator conveyors can move materials quickly and efficiently, reducing the need for manual labor and increasing throughput.

Versatility: Bucket elevator conveyors can handle a wide range of materials, including fine powders, bulky grains, and abrasive materials.

Space-saving: Bucket elevator conveyors have a small footprint, making them ideal for use in facilities with limited space.

Key components of a bucket elevator conveyor

- Buckets: These are the containers that hold the material being transported.

- Chains or belts: These move the buckets along the conveyor.

- Pulleys: These guide and support the chains or belts.

- Drive unit: This provides the power to move the conveyor.

- Discharge mechanism: This releases the material from the buckets at the desired location.

Design considerations for bucket elevator conveyors

Material properties: The type and properties of the material being transported will affect the design of the conveyor, including the size and shape of the buckets, the speed of the conveyor, and the type of chain or belt used.Lift height: The distance between the top and bottom of the elevator will affect the design of the conveyor, including the size and spacing of the buckets, the strength of the chains or belts, and the power of the drive unit.

Throughput: The desired throughput will affect the design of the conveyor, including the speed of the conveyor, the size and shape of the buckets, and the power of the drive unit.

Maintenance and troubleshooting of bucket elevator conveyors

Regular maintenance and troubleshooting are important to ensure optimal performance and prevent downtime. Here are some tips for maintaining and troubleshooting your bucket elevator conveyor:- Regularly inspect and clean the buckets, chains, and pulleys to prevent buildup and damage.

- Lubricate the chains or belts regularly to reduce friction and wear.

- Check for loose or damaged components and replace them as needed.

- Monitor the performance of the drive unit and adjust as needed to maintain the desired throughput.

- Regularly check for signs of wear or damage on the conveyor components and replace them as needed.

- Troubleshoot issues such as jamming, slipping, or material buildup by inspecting the components and adjusting as needed.

Safety considerations for bucket elevator conveyors

Bucket elevator conveyors can be dangerous if proper safety precautions are not taken. Here are some safety considerations to keep in mind:- Provide proper training for operators on the safe use and maintenance of the conveyor.

- Install guards and covers to prevent access to moving parts.

- Use proper lockout/tagout procedures when performing maintenance or repair.

- Regularly inspect the conveyor for signs of wear or damage and address any issues promptly.