Benefits of Fexible Screw Conveyor

A flexible screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water. [Wiki] The screw conveyor auger have many names such as flex conveyors, flexible spiral conveyors, helix or helical conveyors, and more.They have become a great option for transferring sluggish to free-flowing material, and we will walk through the basics of screw conveyor below.

The operating principle of auger screw feeder is simple. The twisted screws rotate within a tube and create a directional force. The force moves the material upward through the tube from the entrance of the equipment to the discharging point. Both, the screw and tube are flexible within the desired range and best suited for the type of material being conveyed.

● It is of advanced technology and easy to maintain.

● It can handle different types of material type. It can be sluggish or it can be free-flowing.

There are multiple inlets and discharge points. It can discharge materials at various points where needed. One can also control the flow of the material with the help of a slide gate or valve.

● They are adjustable and one can accommodate in smaller spaces.

● Screw conveyors can hold on to the internal pressure and vapor. This is very important when we want to handle materials that are toxic or hazardous.

● Screw conveyors are easy to install and more secured when it comes to working at a higher position.

● Screw conveyor is used for mixing various materials and for breaking lumps in some industries.

● A customized screw conveyor that is made without a center pipe is used in transporting wet, sluggish, sticky kinds of materials in the industries.

● Screw conveyors can also help in heating, cooling, or drying the materials.

Gravity spiral conveyor are amongst the most widely used types of conveyors. They can transfer different types of free-flowing as well as non-free-flowing materials such as powder, granules, and small pellets using a spiral-shaped auger inside a casing.

All in all, food grade screw conveyors are an ideal choice for batch-type processing applications. They have become an attractive equipment option owing to their simple construction, straightforward operation, low maintenance, and many more. Contact Focusconveyor - one of the professional screw auger conveyor manufacturers today!

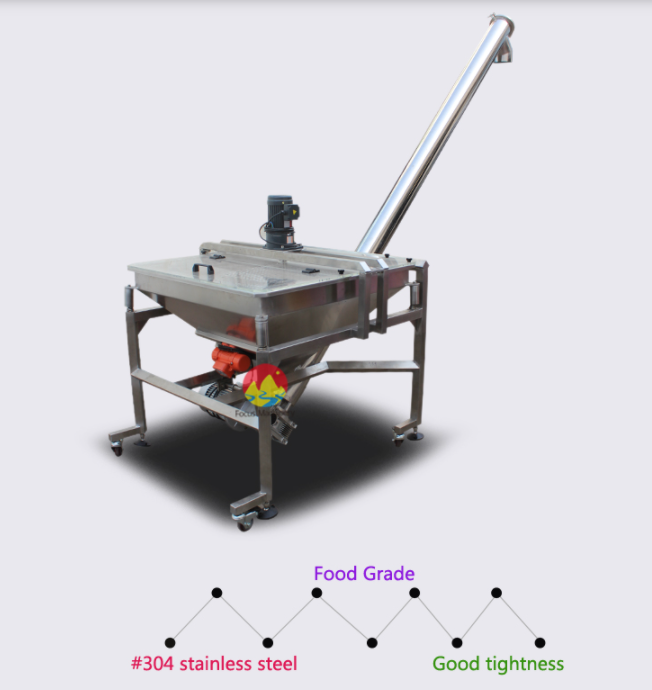

screw auger conveyor or flexible screw conveyor for sale

Working principle of auger screw conveyor:

The operating principle of auger screw feeder is simple. The twisted screws rotate within a tube and create a directional force. The force moves the material upward through the tube from the entrance of the equipment to the discharging point. Both, the screw and tube are flexible within the desired range and best suited for the type of material being conveyed.

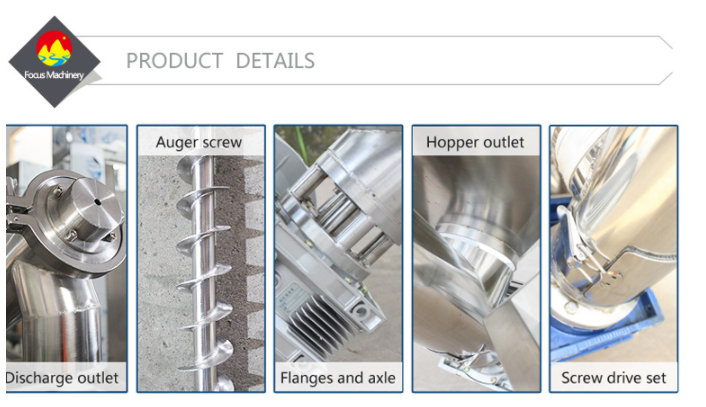

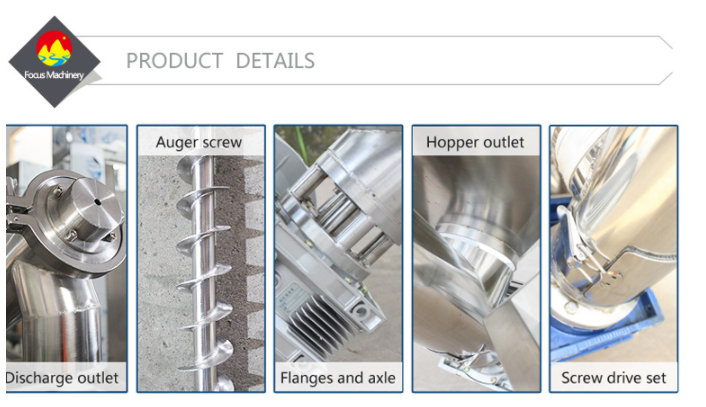

Details of vertical helical screw conveyor

Advantages of spiral conveyor:

● It is of advanced technology and easy to maintain.

● It can handle different types of material type. It can be sluggish or it can be free-flowing.

There are multiple inlets and discharge points. It can discharge materials at various points where needed. One can also control the flow of the material with the help of a slide gate or valve.

● They are adjustable and one can accommodate in smaller spaces.

● Screw conveyors can hold on to the internal pressure and vapor. This is very important when we want to handle materials that are toxic or hazardous.

● Screw conveyors are easy to install and more secured when it comes to working at a higher position.

● Screw conveyor is used for mixing various materials and for breaking lumps in some industries.

● A customized screw conveyor that is made without a center pipe is used in transporting wet, sluggish, sticky kinds of materials in the industries.

● Screw conveyors can also help in heating, cooling, or drying the materials.

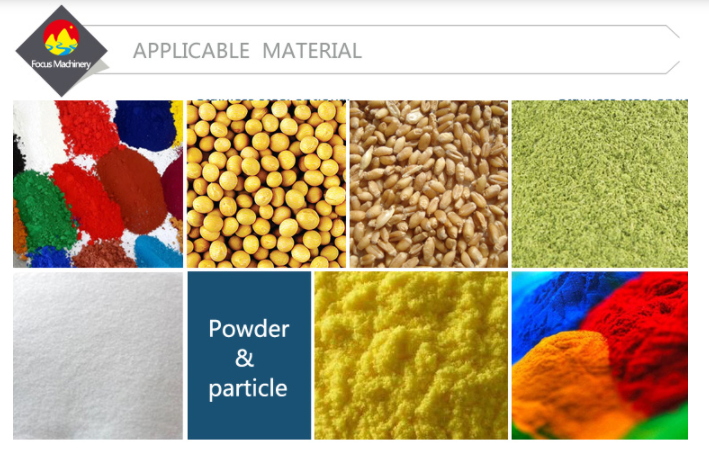

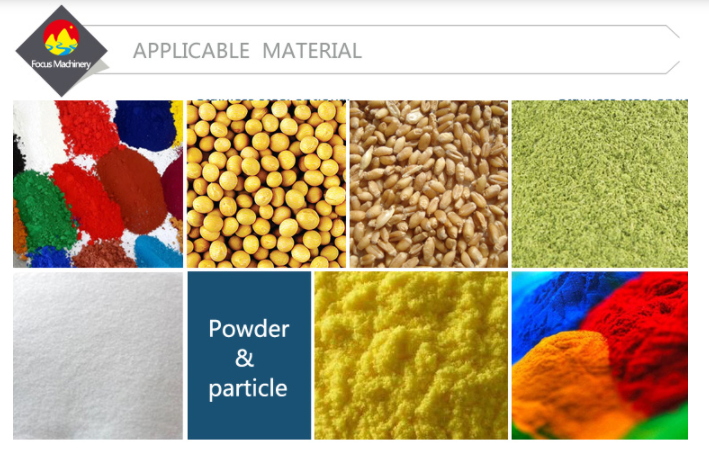

Applications of flexible spiral conveyor:

Gravity spiral conveyor are amongst the most widely used types of conveyors. They can transfer different types of free-flowing as well as non-free-flowing materials such as powder, granules, and small pellets using a spiral-shaped auger inside a casing.

Applications of vertical screw conveyor

Conclusion

All in all, food grade screw conveyors are an ideal choice for batch-type processing applications. They have become an attractive equipment option owing to their simple construction, straightforward operation, low maintenance, and many more. Contact Focusconveyor - one of the professional screw auger conveyor manufacturers today!